Copyright @ Jinjiang Shangli Machinery Equipment Manufacturing Co., Ltd..All rights reserved 闽ICP备19011283号-1 Powered by:300.cn

PRODUCTS

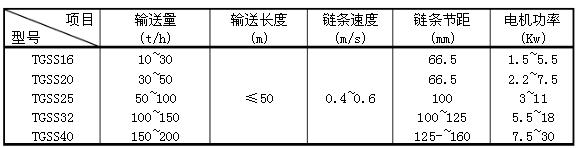

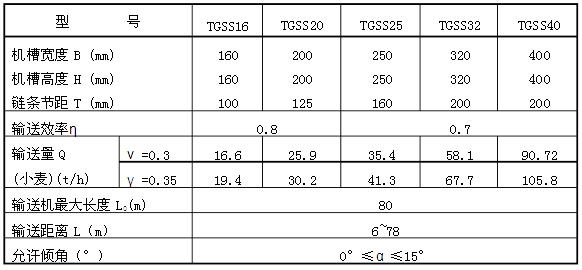

TGSS scraper conveyor

The scraper conveyor is a continuous transportation equipment that transports scattered materials by means of a moving scraper chain in a closed large cross-section shell; Since the scraper chain is buried in the material when transporting the material, this is the reason why it is called the scraper conveyor. This series of buried scraper conveyor products have the characteristics of simple structure, good sealing, convenient installation and maintenance, and flexible process layout. Burial scraper conveyor products can not only transport horizontally, but also tilt or vertical transport; It can be used either individually or jointly; Can add more, can also unload more.