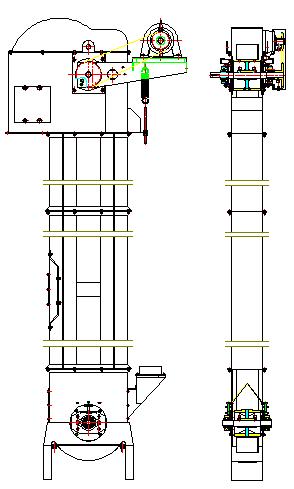

1, the nose is composed of head seat, cover, bearing seat, main shaft and head wheel and other parts. The nose adopts a split structure and is easily installed and dismantled. The top is provided with explosion proof mouth to ensure safety; The lower part is equipped with a suction outlet to facilitate the installation of a pressure balance pipe or a suction pipe to ensure that the internal pressure of the nose and seat is balanced and that dust spills are prevented.

2, riser: with three types of riser, that is, with the observation window riser, with the operating door riser and ordinary riser. It is formed by pressing the thin steel plate and welding with the corner steel flange at both ends. The standard height of the riser is 2000 mm. The observation window Guanji operation door riser should be made on the 2000 mm riser.

3, seat: by the seat body, tail wheel, tail axle, bearing seat, tensioning device, plug door and feed bucket and other parts. The feed Hopper installation device is arranged on the forward feed or reverse feed end of the machine base according to the process design requirements. There is a row of plug doors at each end of the seat. Open the plug door to clearly identify the residue in the seat. The tensioning device is used to adjust the looseness of the belt and correct the deviation. The tensioning system specially designed by this series of hoists has the advantages of simple structure and convenient adjustment.

4, dustbucket: Made of thin steel plate, its geometry and size design is powder, the general type of particles. When used for lifting loose powder materials, it is best to use the bottom with holes in the dustbucket, which is more conducive to full unloading of the material to reduce the dustbucket material and reflux phenomenon. The bucket can also be made of nylon materials. Its advantage is that it is light and flexible, reducing power loss, and is suitable for some powders that do not wear much on the material.

5, belt: generally recommended to use high-strength polyester rubber tape, but also according to the user's economic situation to select ordinary multi-layer rubber tape. The joint at both ends of the dustbucket belt can be connected by belt bolts. The dustbucket is fixed on the dustbucket belt with a dustbucket screw.