Copyright @ Jinjiang Shangli Machinery Equipment Manufacturing Co., Ltd..All rights reserved 闽ICP备19011283号-1 Powered by:300.cn

PRODUCTS

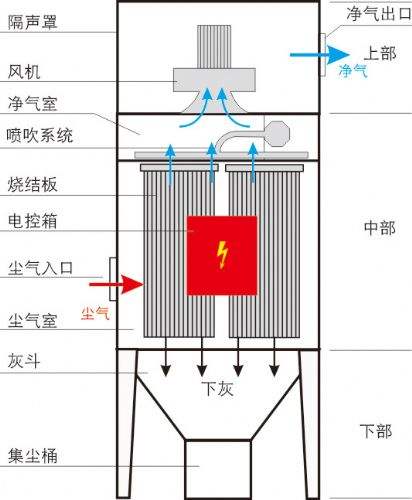

Plastics sintering board(sintering board) dust remover

The high temperature sintering board dust collector is mainly a new generation of dust collector developed for high-temperature gas dust removal. The substrate is clay, glass and other materials, and the temperature up to 350 °C has excellent chemical stability. The cylindrical filtration unit can be better coated with inorganic coating on the outer surface. Surface filtering. The sintering plate filter contains one or more groups of filtration unit clusters, each consisting of multiple filter rods. The cluster filter unit can be easily installed from the side of the Clean Air chamber. Plastics burn board precipitators can effectively capture dust of 0.1 μm or more, and the collection efficiency of dust above 1 μm is as high as 99.99 %, and the emission is less than 1 mg/m3, which achieves zero emission in the true sense.